The Covid pandemic and the global socio-economic crisis have created new challenges in the supply chain. In order to overcome them, companies must take one step further – moving from traditional approaches of data processing for making complex decisions towards more agile, efficient and precise business decision-making. This is supported by innovative software solutions based on AI and ML technologies. One such solution is BE-terna’s AI platform for sales forecasting and inventory optimization, which has recently become available on our Marketplace.

We spoke with Milan Listeš, BE-terna’s Customer Landing Manager, and discussed the benefits of automating processes in the supply chain. Through practical examples, we discovered how the BE-terna AI platform enables optimization of business processes with the help of artificial intelligence.

1. What kind of problems and challenges does the BE-terna solution help solve and which companies is it primarily intended for?

The primary goal of our solution is to help companies automate supply chain processes through the introduction of artificial intelligence (AI). This is to ensure that complex decisions are not made after lengthy manual data processing, but based on automated suggestions of various artificial learning algorithms. These algorithms take into account a substantial amount of data – both internal and external.

The benefits of using our solution can be experienced by all companies where ordering of goods and inventory is at the heart of their business. This could include manufacturing companies having challenges with ordering of raw materials or companies facing issues with production planning. It can also include companies that deal with distribution – all the way to various retail chains, whether they deal with consumer goods, drugs, medical equipment, auto parts, fashion, etc. Also, one of the niche positions where our solution can be of great value is in huge manufacturing or energy plants, at the time of ordering spare parts for necessary maintenance works.

2. What are the main advantages of your solution from the technological and business aspects?

Normally, the way we position a solution on the market is via a cost-benefit analysis. The reason being is that there are very measurable results that are a consequence of using our solution, and this is primarily about the reduction of inventory levels, as well as stock-out situations that directly lead to a reduction in missed sales. Thus, a better inventory structure is visible through a faster inventory turnover ratio.

One of the main differences of our platform compared to other solutions available on the market is that we easily integrate into all existing ordering processes that users already have and use. This leads us to a key technological advantage, which is that we practically offer “Intelligence as a Service” instead of another piece of software that the user merely installs.

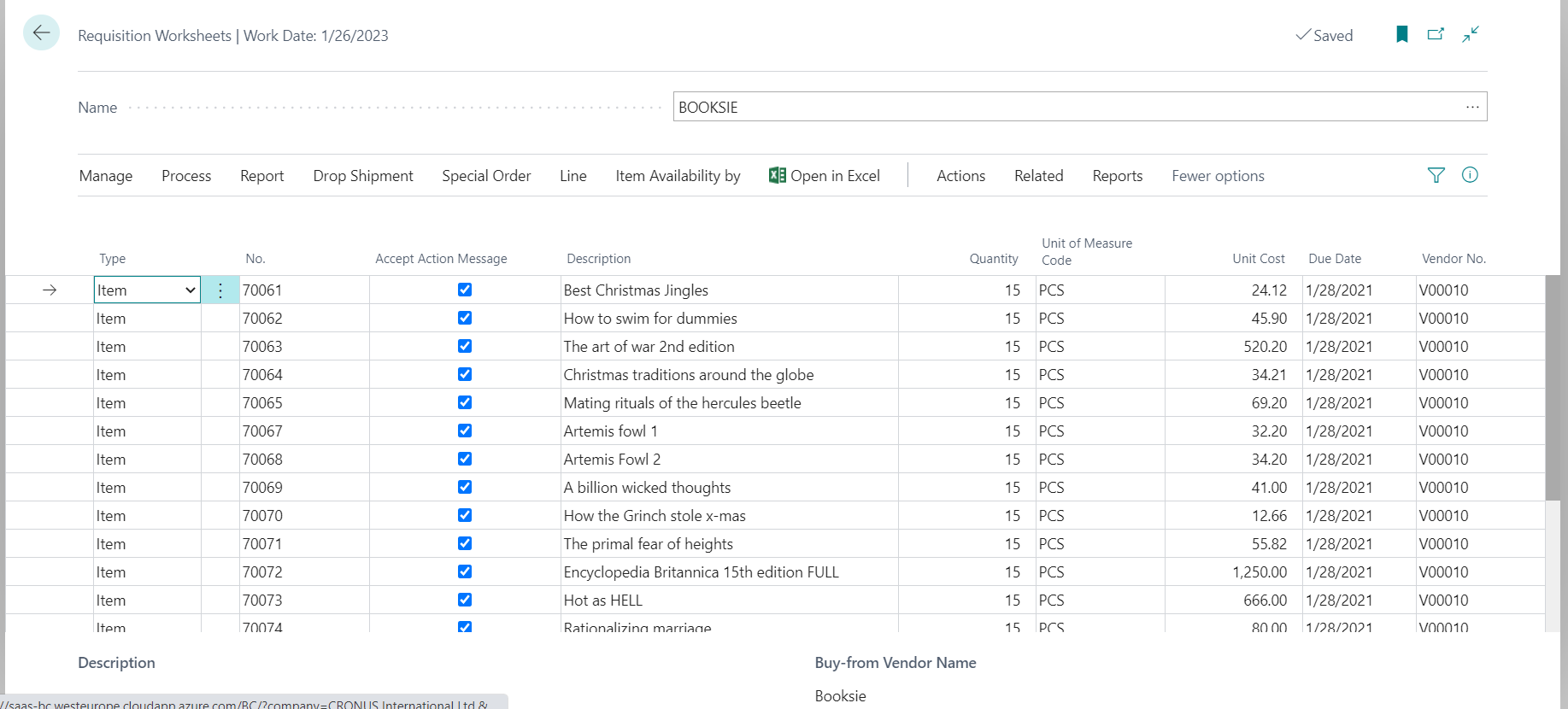

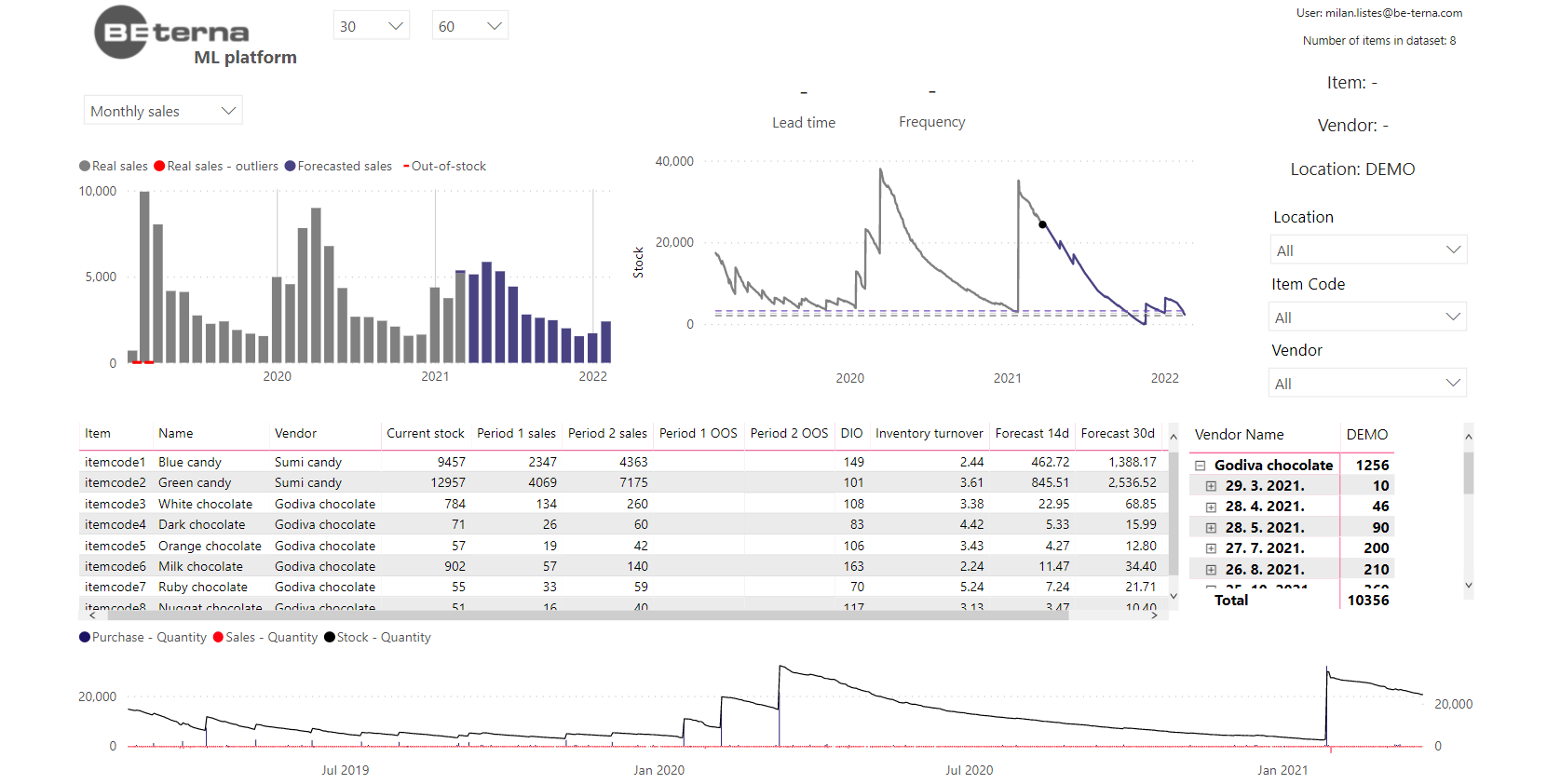

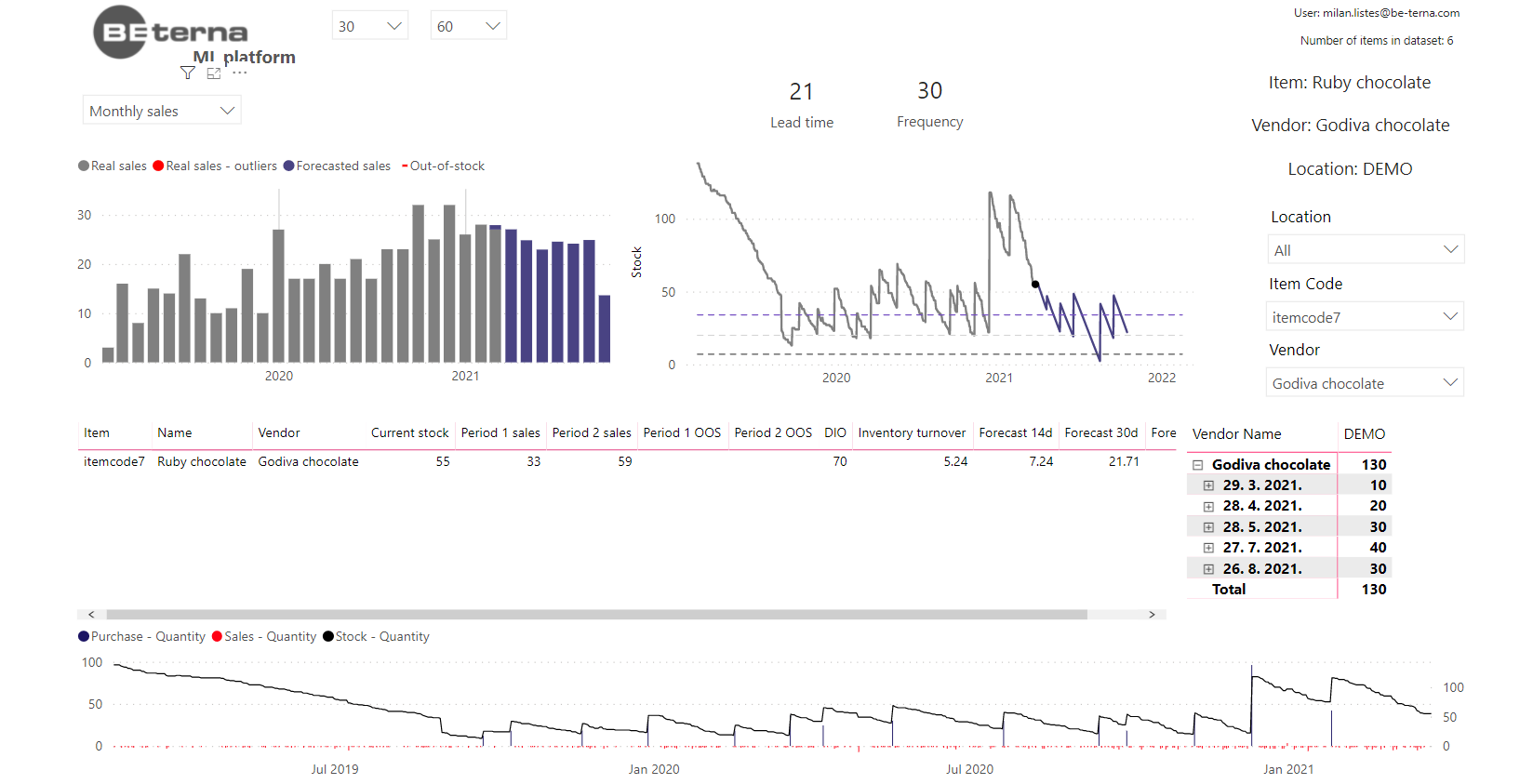

Proposals for ordering goods that are the result of use of our platform are directly integrated into the ERP system, or another place from which the user makes an order to his supplier. Also, the process includes the use of modern machine learning algorithms, the use of external data, and the integration of data on the real position of cargo transport.

3. How easy is your solution to use and what customization and integration options are available?

Our solution can be used with relative ease as described in the previous question. Our platform has only two focal points with end users, namely: direct integration of the proposal for ordering goods with the ERP system of the user and a simple BI application through which we provide end users with context and clarification of each proposal for ordering. This component proved to be critical for the success of the projects and for the acceptance of the solution by the end users.

4. From your experience, what are the main challenges in supply chain and demand forecasting?

I believe that the challenges which the Covid-19 pandemic brought to supply chains are already known to everyone, and on top of that, the old ones have not disappeared either.

Predicting when goods need to be refilled, managing their allocation and dealing with items that have different seasonality or different life cycles and sales frequencies is a complex job if you are dealing with 500 items. And the same can be said if you are a FMCG retail chain that works with 20-30,000 items or a retail chain of automotive spare parts with 200,000 items.

Forecasting the sales of such a large number of different items is a task that is much easier to do with modern technology than manually. Therefore, using our solution without a doubt gives positive results in the context of savings and a better level of service you provide to your end users.

5. Can you provide examples of companies that have improved their business with your solution?

One example of a successful implementation of our solution for inventory optimization and sales forecasting is the company Salus Group. The company specializes in the provision of distribution, promotion and sales services, as well as activities that ensure that medical products and medical devices will be available on the market. Over time, as the company's reach and range of services increased, the manual ordering processes became too complex and ineffective. Thus, in such situations it was impossible to have a proper system of forecasting due to all the different types of items. Through the implementation of our solution, we delivered successful results in three key areas:

- Predicting future demand for 85% of items: Our platform predicts demand with a high certainty for up to 85% of items using historical and third-party data. In this way, we significantly facilitated the work in the procurement sector.

- Minimization of stock-out situations by over 90%: Through continual improvement of safety stock levels and constant monitoring of market needs, we managed to reduce stock-out situations by over 90% thanks to our platform.

- Reduction of up to 50% of manual input time: Manual time is reduced by 50% for all team members, allowing them to focus on high-value non-standard items.

6. What are the main benefits of the cloud deployment model for users? As a software company, how do you see the future of SaaS solutions - is there increasing demand for this type of delivery model?

From our perspective, the benefits are visible in many fields, especially for smaller users who may not have an existing infrastructure, so the marginal cost of installing a new system would be significantly higher for them. For smaller companies, the cloud has greatly accelerated the journey from idea to realization. When we talk about implementation, we really refer to the end user coming in to work in the morning and using the results of the nightly data processing of a large number of algorithms which give a suggestion of just how many goods need to be ordered.

We also decided to use this concept in the development of our cloud-based solution, and practically only the end result, as we mentioned, is integrated with the client's systems.

Of course, we are flexible and can also support on-prem installations, but more and more companies, especially for projects in the world of AI, decide to test (and ultimately use) solutions in the cloud since this delivery model allows them to be more efficient and thus achieve results much more quickly.

Take the first step towards optimizing your supply chain

For more information on how BE-terna's cloud AI platform can help you take control of your inventory and predict demand, contact us for a free consultation.